In the intricate ecosystem of vehicle mechanics, the role of oxygen sensors is paramount. At www.techiebulb.com, we delve into the depths of this crucial automotive component to provide you with comprehensive insights into the various types of oxygen sensors available in the market today.

An oxygen sensor, often referred to as an O2 sensor or Lambda sensor, is a small but mighty device nestled within a vehicle’s exhaust system. Its primary function is to monitor the level of oxygen in the exhaust gases, providing essential feedback to the engine control unit (ECU) to ensure optimal combustion efficiency.

Working principle of Oxygen Sensor

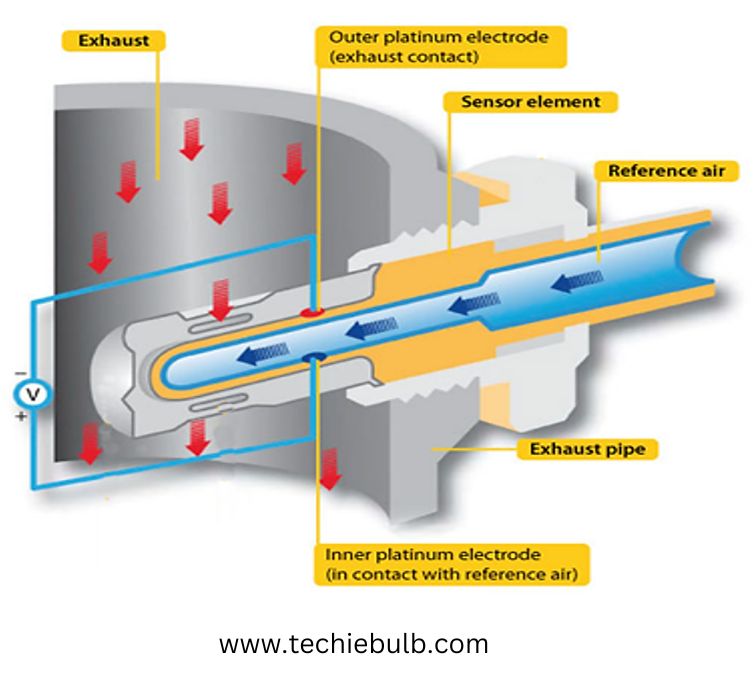

The oxygen sensor operates on a sophisticated principle known as the galvanic oxygen concentration cell with solid electrolyte, rooted in Nernst’s principle. This intricate mechanism involves a ceramic sensing element that serves as a conductor of oxygen ions, starting its functionality at a temperature of 350°C. Let’s delve into the details of how this ingenious system works.

The core principle involves a galvanic cell designed to measure the concentration of oxygen. This cell consists of a solid electrolyte, and its operation is governed by Nernst’s principle, which describes the relationship between the concentration of reactants and the voltage potential of an electrochemical cell.

The heart of the oxygen sensor is the ceramic sensing element. Acting as a conduit for oxygen ions, this element is pivotal in detecting and measuring the oxygen concentration within the exhaust gases.

To facilitate its operation, the sensing element is equipped with an integrated heater. This heater is crucial, especially during the initial stages when the exhaust gases are not hot enough to activate the sensor. The heating element ensures the sensor reaches its operational temperature efficiently.

The oxygen sensor is strategically placed in the exhaust manifold, a location where it can effectively sample the exhaust gases. This positioning ensures accurate readings, reflecting the true composition of the gases leaving the engine.

Significance of Oxygen Sensors

The efficiency of a vehicle’s engine largely depends on maintaining the correct air-fuel ratio. Oxygen sensors play a pivotal role in this process by continuously measuring the oxygen levels in the exhaust gases, allowing the ECU to make real-time adjustments for peak performance.

Different Types of Oxygen Sensors

1. Zirconia Oxygen Sensors

Known for their durability and precision, zirconia oxygen sensors are a popular choice in modern vehicles. They operate based on the principle of generating voltage in response to the oxygen concentration in the exhaust gases, ensuring accurate readings for efficient fuel combustion.

At the heart of Zirconia Oxygen Sensors lies the use of zirconia crystals, a material known for its robustness and stability. These sensors leverage the unique properties of zirconia to provide accurate readings of oxygen levels in a vehicle’s exhaust gases.

Zirconia Oxygen Sensors operate on a simple yet ingenious principle. As exhaust gases pass over the zirconia crystal, a voltage is generated based on the oxygen concentration. This voltage signal is then transmitted to the engine control unit (ECU), allowing for real-time adjustments to the air-fuel mixture.

Zirconia’s inherent stability and resistance to corrosion make these sensors exceptionally durable. Their ability to withstand the harsh conditions within an exhaust system ensures consistent and reliable performance over the long term.

2. Titania Oxygen Sensors

Titania oxygen sensors are another variant, relying on titanium dioxide as the sensing element. These sensors are particularly effective in detecting variations in the oxygen levels during combustion, aiding in maintaining the optimal air-fuel ratio.

At the core of Titania Oxygen Sensors lies the use of titanium dioxide as the sensing element. This innovative approach sets them apart, offering a robust solution for measuring oxygen concentrations with remarkable accuracy.

Titania Oxygen Sensors function by leveraging the conductivity changes in titanium dioxide based on the oxygen levels in the exhaust gases. This dynamic process ensures a real-time stream of data that allows the engine control unit (ECU) to make swift and precise adjustments to the air-fuel mixture.

One of the primary advantages of Titania Oxygen Sensors is their heightened sensitivity to variations in oxygen levels. This makes them particularly adept at maintaining the optimal air-fuel ratio, contributing to enhanced engine efficiency and fuel economy.

Titania Oxygen Sensors showcase remarkable resilience to temperature fluctuations. This attribute ensures consistent and accurate readings even in challenging operating conditions, making them a reliable choice for a diverse range of vehicles.

3. Wideband Oxygen Sensors

Wideband oxygen sensors are the tech-savvy solution for advanced engine management systems. Their ability to provide a broader and more accurate measurement range makes them indispensable in high-performance and fuel-efficient vehicles.

Wideband Oxygen Sensors, in contrast to their traditional counterparts, boast an expanded measurement range. This advancement allows them to provide a more comprehensive and accurate assessment of oxygen levels in the exhaust gases.

The operational brilliance of Wideband Oxygen Sensors lies in their ability to deliver precise readings across a broad spectrum of air-fuel ratios. This high-tech precision is particularly beneficial in fine-tuning modern engines for optimal performance and fuel efficiency.

The wider measurement range of these sensors enables more sophisticated engine management strategies. Vehicles equipped with Wideband Oxygen Sensors can achieve a finely tuned air-fuel mixture, leading to improved combustion efficiency and power delivery.

Wideband Oxygen Sensors play a pivotal role in enhancing fuel efficiency while simultaneously reducing harmful emissions. This dual impact aligns with the growing emphasis on sustainable and eco-friendly automotive solutions.

Wideband Oxygen Sensors find their niche in high-performance vehicles where precise air-fuel ratio control is paramount. Their adoption is particularly prevalent in sports cars, race cars, and vehicles featuring advanced engine management systems.

Modern vehicles equipped with Wideband Oxygen Sensors benefit from advanced engine diagnostics. The real-time data provided by these sensors allows for immediate adjustments, ensuring optimal engine performance under various driving conditions.

4. Heated Oxygen Sensors

Heated Oxygen Sensors, as the name suggests, integrate an internal heating element. This feature ensures that the sensor quickly reaches its operating temperature during cold starts, allowing for swift and accurate readings of the oxygen levels in the exhaust gases.

In colder climates or during a cold start, heated oxygen sensors come into play. Equipped with an internal heating element, these sensors reach operating temperatures more quickly, ensuring accurate readings from the moment the engine is ignited.

The primary function of Heated Oxygen Sensors is to overcome the limitations of traditional sensors in colder climates. By maintaining an optimal operating temperature, these sensors provide consistent and reliable data even in chilly environments.

One of the key advantages of Heated Oxygen Sensors is their contribution to improved cold start performance. The rapid heating ensures that the sensor becomes active faster, allowing the engine control unit (ECU) to make timely adjustments for an efficient air-fuel mixture.

Heated Oxygen Sensors play a pivotal role in maintaining a precise air-fuel ratio, contributing to optimal engine combustion. This level of control is especially crucial during the initial moments of engine ignition, where the right mixture is essential for smooth operation.

The implementation of Heated Oxygen Sensors aligns with regulatory standards for vehicle emissions. By ensuring accurate readings even in cold conditions, these sensors contribute to the overall efficiency of emissions control systems.

Choosing the Right Oxygen Sensor for Your Vehicle

Factors to Consider

When selecting an oxygen sensor for your vehicle, several factors come into play. Consider the vehicle’s make and model, the sensor’s compatibility, and the specific requirements of your driving conditions.

Regular Maintenance

Regardless of the type of oxygen sensor your vehicle employs, regular maintenance is crucial. Inspecting for signs of wear, contamination, or degradation ensures that the sensor continues to operate optimally, contributing to the overall efficiency of your vehicle.

The Diagnostic Process

1. Onboard Diagnostics (OBD) Scan

Modern vehicles are equipped with OBD systems that allow for quick and accurate diagnosis of O2 sensor issues. Connecting a diagnostic scanner to the OBD port provides specific error codes that pinpoint the nature of the problem.

2. Visual Inspection

A visual inspection of the O2 sensor and its wiring can reveal issues such as physical damage, corrosion, or loose connections. Any visible problems should be addressed promptly.

3. Testing Sensor Voltage

Using a multimeter, technicians can test the voltage output of the O2 sensor. Deviations from the expected values can indicate sensor malfunction.

Conclusion

In conclusion, the world of oxygen sensors is diverse and nuanced, with each type catering to specific automotive needs. At www.techiebulb.com, we believe that understanding these intricacies empowers vehicle owners to make informed decisions, ensuring their vehicles run at peak performance.